Hands-free and heads-up: AR ‘at work’ in underground construction sites

Though at a relatively early stage in its development history, key players within the sector advise that, considering its benefits as well as its current uses, adopting Augmented Reality (AR) sooner rather than later may be the next big development in construction, enabling early adopters to leverage significant advantages over their competitors. While challenges include the cost of implementation and lack of construction-specific products within the sector, the benefits are manifold, incorporating the real-time visualisation of projects, improved collaboration and communication, increased safety, the ability to implement additional modelling tools and to deliver projects on time within budgets.

“The adoption of cutting-edge virtual and augmented reality technology in industries like construction will be vital in helping us identify new, smarter ways of working.”

— Greg Clark, Secretary of State for Business, Energy and Industrial Strategy

In 2015, Glasgow-based digital media specialist Soluis Group won an Innovate UK funding competition securing investment to trial an asset management system for Crossrail with contractors Laing O’Rourke. The company was awarded £35,000 to develop software that would allow Augmented Reality (AR) technology to be used in Crossrail’s Elizabeth Line sites in London.

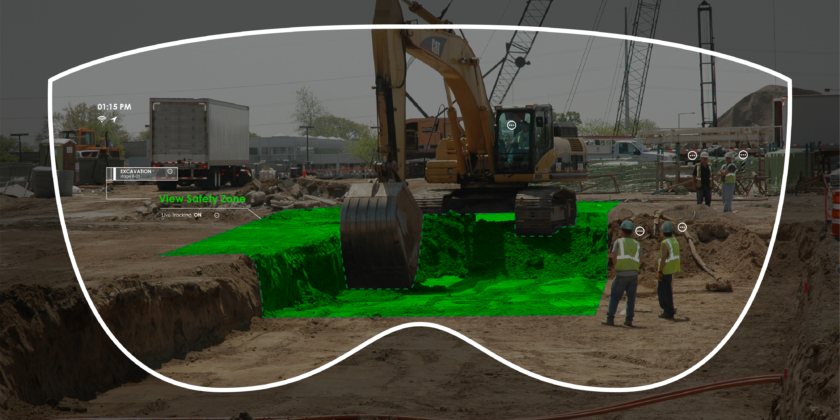

A system that utilised the DAQRI Smart Helmet and the Microsoft HoloLens was created that allowed construction site staff to access and upload Business Information Modelling (BIM) data via the smart helmet’s visor display. Called ‘In-site’, a digital app transferred information about buildings or structures from the cloud to the helmet, overlaying it as augmented reality on the workers’ visor screens.

This pilot project demonstrated the successful application of AR technology in the construction industry. As Martin McDonnell explains: “The proof of concept project with Crossrail showed how this technology could be applied and add incredible value to the industry”

Crossrail’s William Reddaway backs this up: “This was about legacy and understanding what technologies or solutions can have a positive impact, not only on Crossrail, but the industry as a whole.

But this was only the first step in an ambitious Soluis Group project, which Martin McDonnell is now pioneering with a consortium group of industry partners. The vision is to develop this concept much further and create a set of tools that will form the augmented-worker of the future. The group has secured £1 million of funding from the Government’s Innovate UK programme to help it roll out its wearable AR technology to the wider industry. The project will be supported by industry leaders AECOM, Doosan Babcock, Laing O’Rourke, Autodesk and Microsoft, that will comprise a steering group alongside the consortium.

Martin McDonnell takes up the story:

“The system, named the ‘Augmented Worker’ is a pioneering a system that enables the intelligent design, construction, maintenance and whole-life value of buildings, supporting construction and infrastructure growth.”

“Our vision is supported by others in the industry too, and we are working in conjunction with a consortium of partners that will add considerable skills, knowledge and connections. These include, Pinnacle Business Solutions, an information systems consultancy; Carbon Dynamic, an innovative world leading modular timber building construction company; two High Value Manufacturing Catapult centres – the Advanced Manufacturing Research Centre (AMRC) and the Advanced Forming Research Centre (AFRC).”

Key objectives for ambitious goals

The goal is to develop a system that uses a high-tech headset, realising significant value from BIM, to reduce costs and waste by 25% and increase project productivity by 30%. The goals are greater certainty, safety, efficiency and sustainability through the key areas of co-design, digital job guidance, progress monitoring, safety guidance and asset management. Jobs will be delivered on time and to budget, collaboration will be enhanced and communication improved. With on-site safety for workers paramount, the AR technology reduces the need for handheld devices or paper to provide a hands-free, heads-up solution for a greater level of safety.

Alan Grant is the Digital Reality Consultant on the project. He explains the key benefits of this pioneering system:

“On a traditional building site, what you see is what you get. Using digital assets to provide real-time visualisation on site, as well as better collaboration and communication and increased safety, is much more effective.

“We’re moving from a situation where a construction worker recorded details on paper, carried this back to an office, put the details into a computer or even just a paper-file – to a scenario where we’re using the highly advanced technological tools we have today, working with interactive data that has heads-up accessibility.

“The system is conceptually simple but studies show that it raises efficiency considerably.”

Challenges to overcome

And, inevitably, there are challenges to be surmounted. Alan Grant points to the need for a culture change within the industry itself and a need to educate and re-train workforces. “Traditionally we had somebody on a building site with a paper and measuring tape, now we expect them to wear a headset”.

There are also challenges around taking digital objects into harsh environments and accessing relevant data in, for example, sites that are deep underground in environments where IT structures are not in place. In this case data needs to be stored on the AR device, rather than being pulled from the cloud.

To ensure maximum efficiency, high quality data needs to be in place which may involve complex site surveys. “The investment is potentially high”, Alan acknowledges, “but the return on investment will also be high”.

He also flags up an industry fear that increasing technology may “dumb down” the workforce but believes that “this process is actually equipping the workforce with more information to help them to be more efficient”.

And finally: “Human error can still occur within an AR system, but if you miss a step within it, you will be told you have missed it, either by an audio prompt or, if working in a noisy construction environment, by a vibration alert.”

How AR can improve efficiency

The benefits of AR technology in raising efficiency and productivity are illustrated in a recent internal experiment carried out by Boeing. Assessing trainee performance assembling a mock wing on an aircraft, the group was divided into three. Following instructions provided on either a PDF displayed on a desktop computer, on a tablet or animated AR tablet instructions, the study found that the AR-tablet group were 30% faster and 90% more accurate than the others. Discussing the study, Boeing electrical engineer Paul Davies says “If AR continues to prove similarly effective in continued research, it could be ‘huge’ for companies with Boeing’s scale, both in terms of increased quality and decreased cost.”

AR in construction: a vision of the future

The rewards in successful adoption of AR within the industry are many. The ability to navigate all project phases in advance of physical construction will allow users to make key amendments at the design phase, saving costly changes later. It will also enable greater accuracy through provision of site-specific data and project details. The use of AR technology in construction accelerates processes by offering access to an accurate recreation of a physical space, saves time by enabling more efficient planning and saves money through increased accuracy and efficiency.

Commenting on the place of AR in the future of construction, David Philp, BIM Director at AECOM, the global network of Architecture, Engineering, Consulting, Operations, and Maintenance experts, says:

“Construction technology is reshaping how we deliver and maintain our built assets, it is increasingly helping us place digital information into the real world in the right context supporting and augmenting the decision-making process. Real time access to individualised data, analytics and instructions during the construction and operational stages will greatly improve productivity, quality and also help worker well-being. Creating a framework and guidance around the augmented worker is critically important if we are to successfully unlock this value proposition.”

Words by Bernadette Fallon